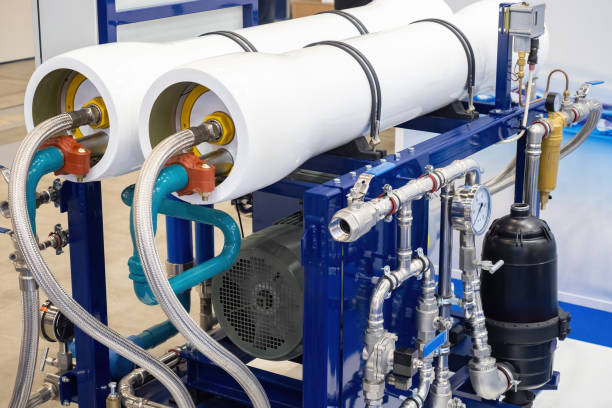

Batch ball mills are the type of mills in which grinding occurs in batches of materials and not continuously as in other types of mills. This technology is especially valuable for experimental work and small scale processes where the control of the grinding environment has to be strict. As batch ball mills are being developed, their uses expand especially in industries that need accurate grinding. This article explores the working of batch ball mills, their benefits and the expanding list of uses, as well as the new developments from China rock crusher and dry ball mill providers.

Basic Operation

Batch ball mills are used for small amounts of material and are used for testing and small scale production. The basic idea of the batch ball mill is that the material is to be ground in a closed system and the balls and the material are to be contained in the mill. This configuration makes it possible to have a good control over grinding parameters and hence have a consistent product with very fine particle size.

Pros of Batch Ball Mills

The main advantage of batch ball mills is that they are versatile and can be used for different materials. Users can control the fineness of the processed materials by varying the milling time, type of grinding media, and other operating factors.

This makes batch ball mills very useful in industries such as ceramics, chemicals, and even the food industry where the size of the particles is very important.

Technological Innovations

Chinese manufacturers are among the leading suppliers of rock crusher and dry ball mill, and they have been incorporating advanced technologies in the batch ball mill designs. These are better materials that are more durable and perform better, automation to have better control of the process, and motors that are energy efficient to cut down on costs. These technological advances assist in keeping the batch ball mills in use in the current industrial processes.

Research and Development

Batch ball mills are widely used in research and development laboratories. Due to their small capacity to process material, they are useful in the testing of new chemical formulations or in the testing of various types of materials in pharmaceutical and material science research.

These mills are very useful in experimental labs due to the high precision and repeatability that they provide.

Cooperation

Technological advancements in the batch ball mill and the dry ball mill suppliers have come up with improvements that make the machines more efficient and useful. For example, dry ball mill manufacturers may offer systems that are suitable for wet and dry milling, which increases the versatility of batch ball mills and the types of materials and processes that they can be used for.

Batch ball mill technology remains relevant in the field of material processing and is widely used in various industries due to its flexibility and relatively low cost. The advancements and upgrades by China rock crusher and dry ball mill suppliers have made sure that this technology is relevant to the current industrial requirements and is still useful to the users globally. Since industries are always in search of better and more efficient milling solutions, batch ball mills are also expected to develop even more sophisticated solutions for material processing.