In the world of modern manufacturing, where precision and efficiency are paramount, mould companies and plastic parts manufacturers play an indispensable role. Whether it’s the automotive industry, consumer electronics, or medical devices, the intricate process of mould making and plastic manufacturing ensures that the products we use every day are of the highest quality. But what exactly do these companies do, and why are they so crucial to the manufacturing process? In this article, we’ll delve into the world of mould companies and plastic parts manufacturer, exploring their processes, challenges, and the innovations driving the industry forward.

Understanding Mould Companies

What Are Mould Companies?

Mould companies specialize in designing and creating moulds, which are essential tools in the manufacturing process. These moulds are used to shape materials, most commonly plastics, into the desired forms for various products. Think of moulds as the blueprints that determine the final shape, size, and even the texture of a product.

The Role of Mould Companies in Manufacturing

Without mould companies, mass production of products would be nearly impossible. These companies provide the foundation for creating everything from car parts to household items. The accuracy and durability of the moulds they produce directly affect the quality and consistency of the final products.

Key Services Providxed by Mould Companies

Mould companies offer a range of services beyond just mould creation. These include prototyping, product design consulting, and maintenance of moulds. They also provide repairs and modifications, ensuring that the moulds continue to produce high-quality products over time.

The Process of Mould Making

Designing the Mould

The first step in mould making is the design process. Engineers work closely with manufacturers to create a detailed blueprint of the mould. This design must take into account the material properties, the product’s intended use, and the manufacturing process.

Material Selection for Mould Making

Choosing the right material for the mould is critical. Common materials include steel, aluminum, and various alloys. The choice depends on factors like the expected production volume, the complexity of the design, and the type of material that will be moulded.

Steps in Mould Manufacturing

Mould manufacturing involves several steps, including machining, polishing, and testing. Each step requires precision to ensure the mould can produce thousands, if not millions, of identical parts with minimal variation.

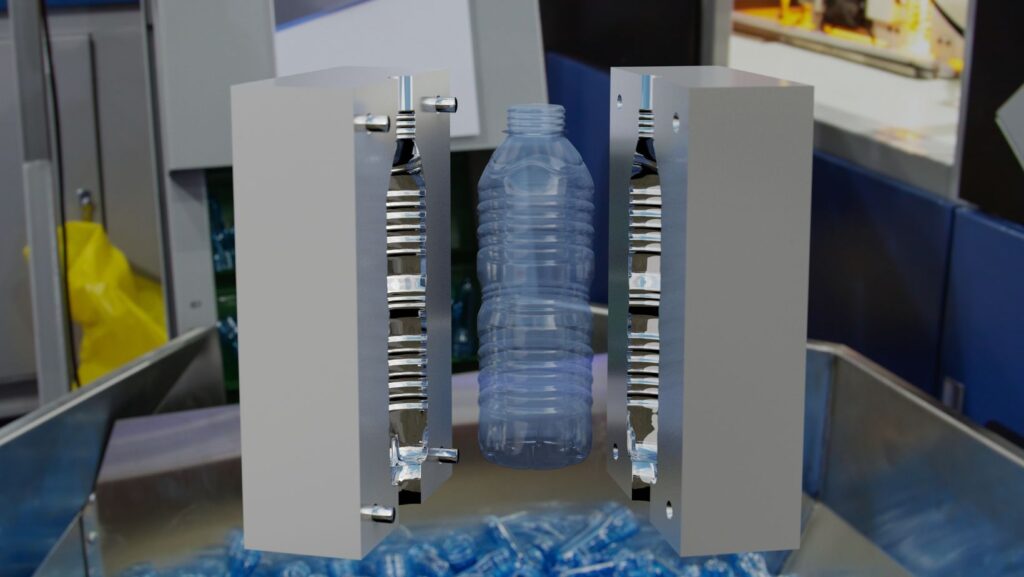

Types of Moulds Used in Plastic Manufacturing

Injection Moulds

Injection moulds are the most commonly used in plastic parts manufacturing. They work by injecting molten plastic into a mould cavity, where it cools and hardens into the desired shape. This method is ideal for producing large quantities of parts with high precision.

Blow Moulds

Blow moulds are used to create hollow plastic parts, such as bottles and containers. The process involves inflating a heated plastic tube inside a mould until it takes the shape of the mould cavity.

Compression Moulds

Compression moulding involves placing a plastic material in a heated mould cavity and then applying pressure to shape it. This method is often used for larger and thicker plastic parts.

Transfer Moulds

Transfer moulding is similar to compression moulding but involves transferring the plastic material from a holding chamber into the mould. This method is used for more complex shapes and is common in the electronics industry.

Importance of Precision in Mould Making

Impact on Product Quality

Precision in mould making is crucial because even the smallest error can result in defective products. High precision ensures that each part produced is identical, reducing waste and improving overall product quality.

Cost Efficiency and Waste Reduction

Accurate moulds contribute to cost efficiency by minimizing material waste and reducing the need for rework. This not only saves money but also speeds up the production process.

Meeting Industry Standards

Moulds must meet strict industry standards to ensure the products they create are safe, reliable, and fit for purpose. This is especially important in industries like automotive and healthcare, where product failure can have serious consequences.

Choosing the Right Mould Company

Factors to Consider: Experience, Technology, and Reputation

When selecting a mould company, it’s important to consider their experience in the industry, the technology they use, and their reputation among clients. Experienced companies are more likely to deliver high-quality moulds that meet specific requirements.

Questions to Ask Before Hiring a Mould Company

Before partnering with a mould company, ask about their previous projects, the materials they work with, and their turnaround times. It’s also wise to inquire about their quality control processes.

Evaluating Past Projects and Client Testimonials

Reviewing past projects and client testimonials can provide insights into the company’s reliability and the quality of their work. Look for companies with a track record of delivering on time and within budget.

Plastic Parts Manufacturing

Overview of Plastic Manufacturing

Plastic manufacturing involves converting raw plastic materials into finished products. This process can include various methods such as injection moulding, blow moulding, and extrusion.

Common Methods in Plastic Parts Manufacturing

The most common methods used in plastic parts manufacturing include injection moulding, blow moulding, and compression moulding. Each method has its own set of advantages and is suited for different types of products.

The Role of Moulds in Plastic Manufacturing

Moulds are essential in plastic manufacturing as they define the shape and structure of the final product.

The quality of the mould directly influences the quality of the plastic parts produced.

Injection Moulding in Plastic Parts Manufacturing

What is Injection Moulding?

Injection moulding is a manufacturing process where molten plastic is injected into a mould to create a part. This method is widely used due to its ability to produce complex shapes with high precision.

Benefits of Injection Moulding

Injection moulding offers several benefits, including high production efficiency, the ability to create complex designs, and minimal waste. It’s also cost-effective for large production runs.

Applications of Injection Moulding in Various Industries

Injection moulding is used in a wide range of industries, including automotive, consumer electronics, and healthcare. It’s particularly valued for its ability to produce durable, high-quality parts quickly and efficiently.

Innovations in Mould and Plastic Parts Manufacturing

Use of Advanced Materials and Technologies

The mould and plastic manufacturing industry is constantly evolving with the introduction of new materials and technologies. These advancements are enabling the creation of stronger, lighter, and more durable products.

Automation and AI in Mould Making and Plastic Manufacturing

Automation and AI are transforming the mould and plastic manufacturing industry by improving precision, reducing costs, and speeding up production times. These technologies are also helping companies to quickly adapt to changing market demands.

Sustainable Practices and Eco-Friendly Materials

As environmental concerns grow, many mould companies and plastic parts manufacturers are adopting sustainable practices.

This includes using eco-friendly materials and reducing waste through more efficient production processes.

Challenges Faced by Mould Companies and Plastic Parts Manufacturers

Adapting to New Technologies

Keeping up with technological advancements is a significant challenge for many mould companies. Those that fail to adapt may struggle to remain competitive in a rapidly changing industry.

Meeting Environmental Regulations

Stricter environmental regulations are pushing mould companies to adopt greener practices. While this is a positive development, it also adds pressure to meet new standards without increasing costs.

Managing Costs and Supply Chain Issues

Rising material costs and supply chain disruptions are ongoing challenges for mould companies and plastic parts manufacturers. Effective cost management and supply chain strategies are crucial for maintaining profitability.

Case Studies: Success Stories in the Mould and Plastic Parts Industry

Example 1: Automotive Industry

In the automotive industry, precision is key. A leading mould company successfully developed a complex mould for a major car manufacturer, resulting in significant cost savings and improved product quality.

Example 2: Consumer Electronics

A mould company specializing in consumer electronics helped a tech giant launch a new product by creating a highly precise mould that enabled mass production without compromising quality.

Example 3: Medical Devices

In the medical device industry, a mould company collaborated with a healthcare provider to develop a custom mould for a life-saving device, showcasing the critical role mould companies play in this sector.

Future Trends in Mould and Plastic Parts Manufacturing

The Rise of 3D Printing and Additive Manufacturing

3D printing and additive manufacturing are revolutionizing the mould and plastic parts industry by allowing for rapid prototyping and customization. These technologies are expected to become even more prevalent in the coming years.

The Impact of Globalization on Mould Companies

Globalization is reshaping the mould industry by increasing competition and driving innovation. Mould companies must adapt to remain competitive in a global market.

The Shift Towards Customization and Small Batch Production

As consumer demand for personalized products grows, mould companies are shifting towards customization and small batch production. This trend is likely to continue as more industries adopt just-in-time manufacturing practices.

Conclusion

Mould companies and plastic parts manufacturers are the backbone of modern manufacturing. Their ability to create precise, high-quality moulds and plastic parts is essential to the production of countless products we rely on daily. As the industry continues to evolve, these companies will play a pivotal role in shaping the future of manufacturing, from adopting new technologies to meeting environmental challenges. Whether you’re in the automotive, electronics, or healthcare industry, partnering with a skilled mould company is key to achieving success in today’s competitive market.