Ever thought about how many everyday items we use that started out as a chunk of metal? From the car you drive to the smartphone in your hand, a lot of the magic happens thanks to a nifty machine called a metal lathe.

Metal lathes have been around for ages, but boy, have they come a long way! Let’s dive into the fascinating journey of metal lathes and see just how much they’ve changed the game in industrial innovation.

A Blast from the Past: The Birth of Metal Lathes

Imagine it’s the late 18th Century. The industrial revolution is just kicking off, and people are hungry for machines that can do more, faster.

Enter the metal lathe.

The early versions were basic—just a simple setup where a piece of metal would spin, and a sharp tool would shape it. Even then, it was like a game-changer. It wasn’t long before these contraptions became the backbone of factories everywhere.

Ancient Beginnings

Going way back, the concept of lathes actually dates to ancient Egypt. Yep, the Egyptians used a rudimentary form of a lathe to shape wood. It was basic, but it got the job done.

Fast forward a few thousand years, and by the time the industrial revolution hit, metal lathes were ready to rock and roll.

The Industrial Boom

In the 19th Century, metal lathes were the stars of the show. They were all about precision, allowing machinists to craft parts that fit together perfectly. It was like moving from drawing with crayons to using a fine-tipped pen. This leap in accuracy meant that everything from engines to tools could be made better and faster. Factories started pumping out products at a pace never seen before.

Talk about a revolution!

Modern Marvels: Lathes in the 20th Century

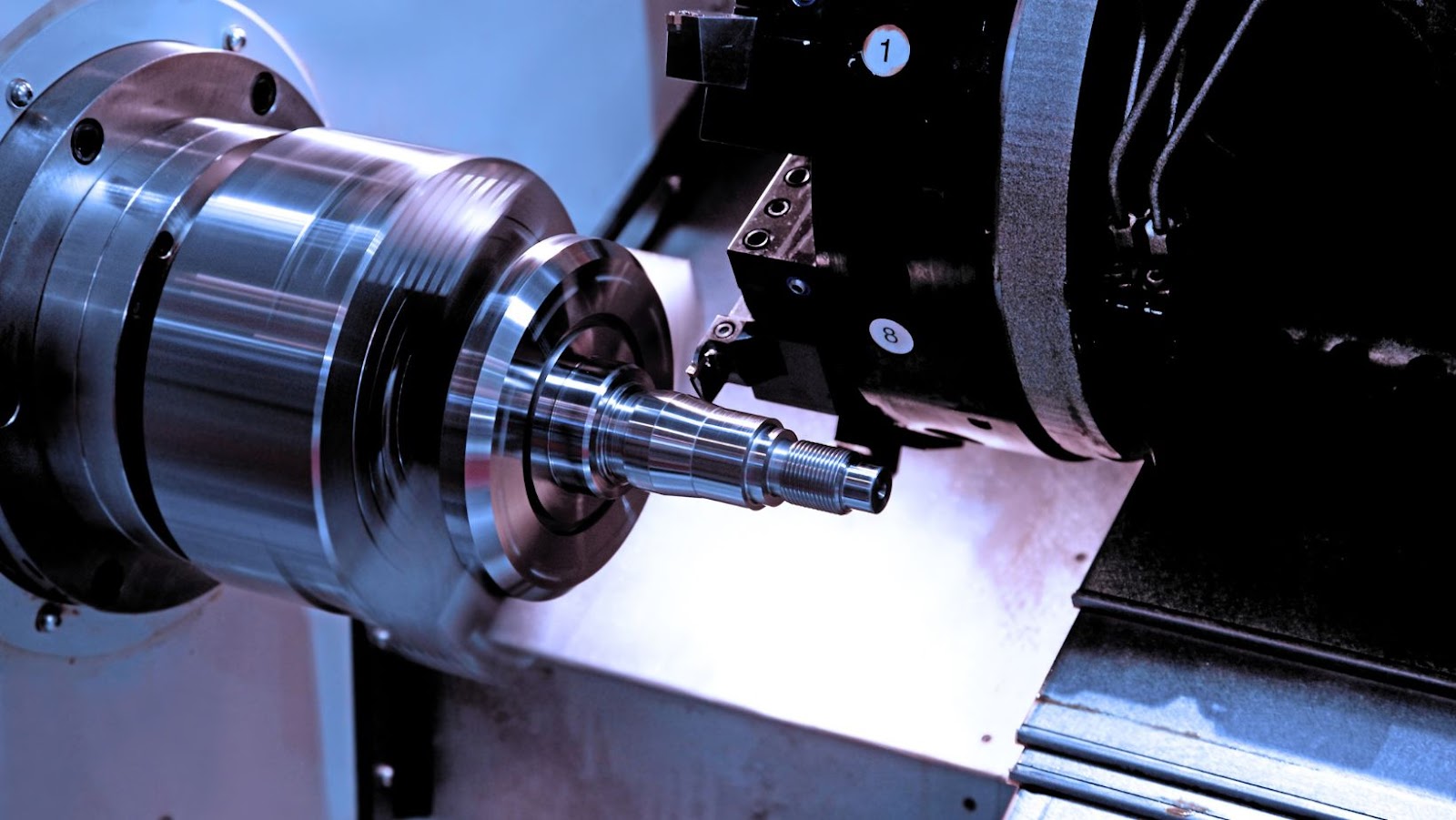

Jump ahead to the 20th Century, and metal lathes have gotten a serious upgrade. They are no longer just mechanical; they’re now powered by electricity and controlled by computers. If the old lathes were like a trusty old bike, modern lathes are like a sleek, high-speed motorcycle.

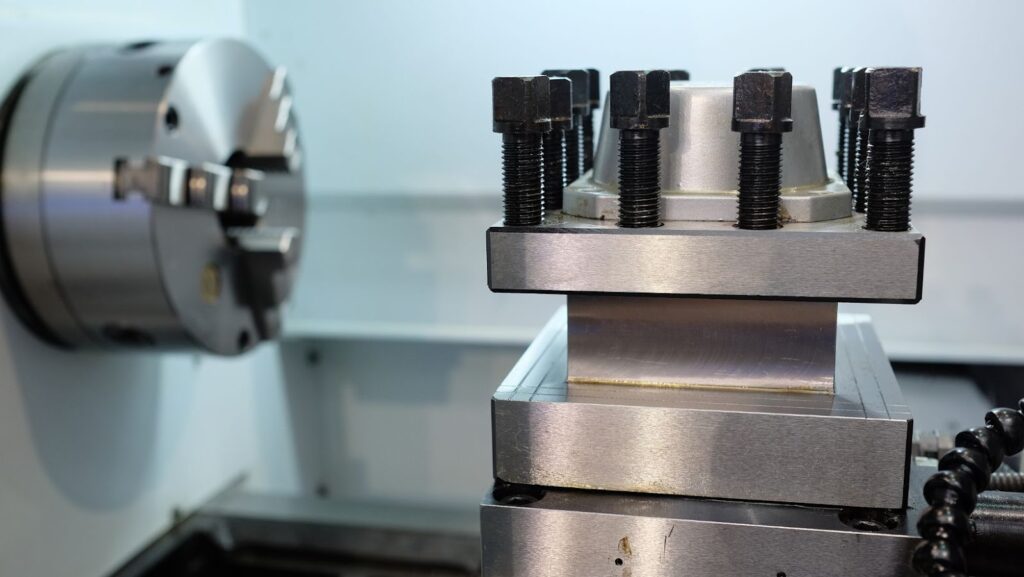

Precision and Automation

The advent of computer numerical control (CNC) was a turning point. With CNC, machinists could program lathes to perform complex cuts with pinpoint accuracy. This wasn’t just a step up; it was a whole new ballgame.

Factories became more efficient, and products became even more reliable. Plus, automation meant that machines could run around the clock. This was huge for industries like automotive and aerospace, where precision and reliability are critical.

Versatility and Speed

Modern metal lathes aren’t just about precision—they’re also incredibly versatile. They can work with a range of materials, from steel to aluminum to exotic alloys. Need a custom part for a prototype? No problem.

Want to churn out thousands of identical pieces? Easy peasy. This flexibility has opened doors for innovation in ways that were previously unimaginable.

The Impact: How Metal Lathes Shaped Industries

So, what’s the big deal about metal lathes anyway? Well, they’ve had a massive impact on pretty much every industry you can think of. Let’s break it down.

Automotive Industry

Think about the car you drive. Almost every part of it—engine components, gears, axles—has likely been touched by a metal lathe. The precision and efficiency of lathes have enabled car manufacturers to produce reliable, high-performance vehicles. Without them, the automotive industry as we know it wouldn’t exist.

Aerospace Industry

In aerospace, precision isn’t just important; it’s a matter of life and death. Metal lathes produce components that meet the stringent standards required for aircraft and spacecraft. They help ensure that every bolt, every turbine blade, every structural component is made to exact specifications. This precision is what keeps planes flying safely and rockets reaching for the stars.

Medical Devices

Metal lathes also play a crucial role in the medical field. Surgical instruments, implants, and diagnostic devices all rely on components crafted by lathes. The ability to create precise, reliable parts means better outcomes for patients and advances in medical technology.

Consumer Goods

Even the gadgets we use daily—smartphones, laptops, appliances—often owe their existence to metal lathes. The precise components needed for these devices are manufactured using advanced lathes, ensuring they work flawlessly and fit together perfectly.

The Future: Where Are Metal Lathes Headed?

You might be wondering, where do we go from here? Well, the future of metal lathes is looking pretty exciting. As technology advances, so too do these versatile machines.

Advanced Materials

One trend is the use of advanced materials. As industries push the boundaries of what’s possible, there’s a growing need for lathes that can handle new, super-strong, and super-light materials.

This will be crucial in fields like aerospace and medical devices, where every gram and every millimeter counts.

Smart Manufacturing

Another big trend is smart manufacturing. Think of the Internet of Things (IoT) but for factories.

Machines that can communicate with each other, optimize their own performance, and predict maintenance needs. Imagine a lathe that tells you when it’s time to change a tool or predicts when a part will wear out.

This kind of innovation will make factories more efficient and reduce downtime.

Sustainability

Sustainability is also a key focus. With the push towards greener manufacturing, future lathes will likely be designed to minimize waste and energy consumption.

This will help industries reduce their environmental footprint and comply with stricter regulations.

Wrapping It Up: Metal Lathes in a Nutshell

From their humble beginnings in ancient Egypt to the high-tech CNC machines of today, metal lathes have come a long way. They’ve revolutionized industries, driven innovation, and played a crucial role in shaping the modern world. And with the rapid pace of technological advancement, who knows what amazing feats they’ll accomplish next?

So, next time you’re driving your car, flying in a plane, or using your smartphone, take a moment to appreciate the metal lathe. It might not be the flashiest machine in the factory, but it’s definitely one of the most important. And if you’re ever in the market, you can find metal lathes for sale that suit all kinds of needs, from hobbyist projects to industrial manufacturing.

In the end, metal lathes are more than just machines. They’re a testament to human ingenuity and our relentless drive to innovate and improve. And that, my friends, is something worth celebrating.