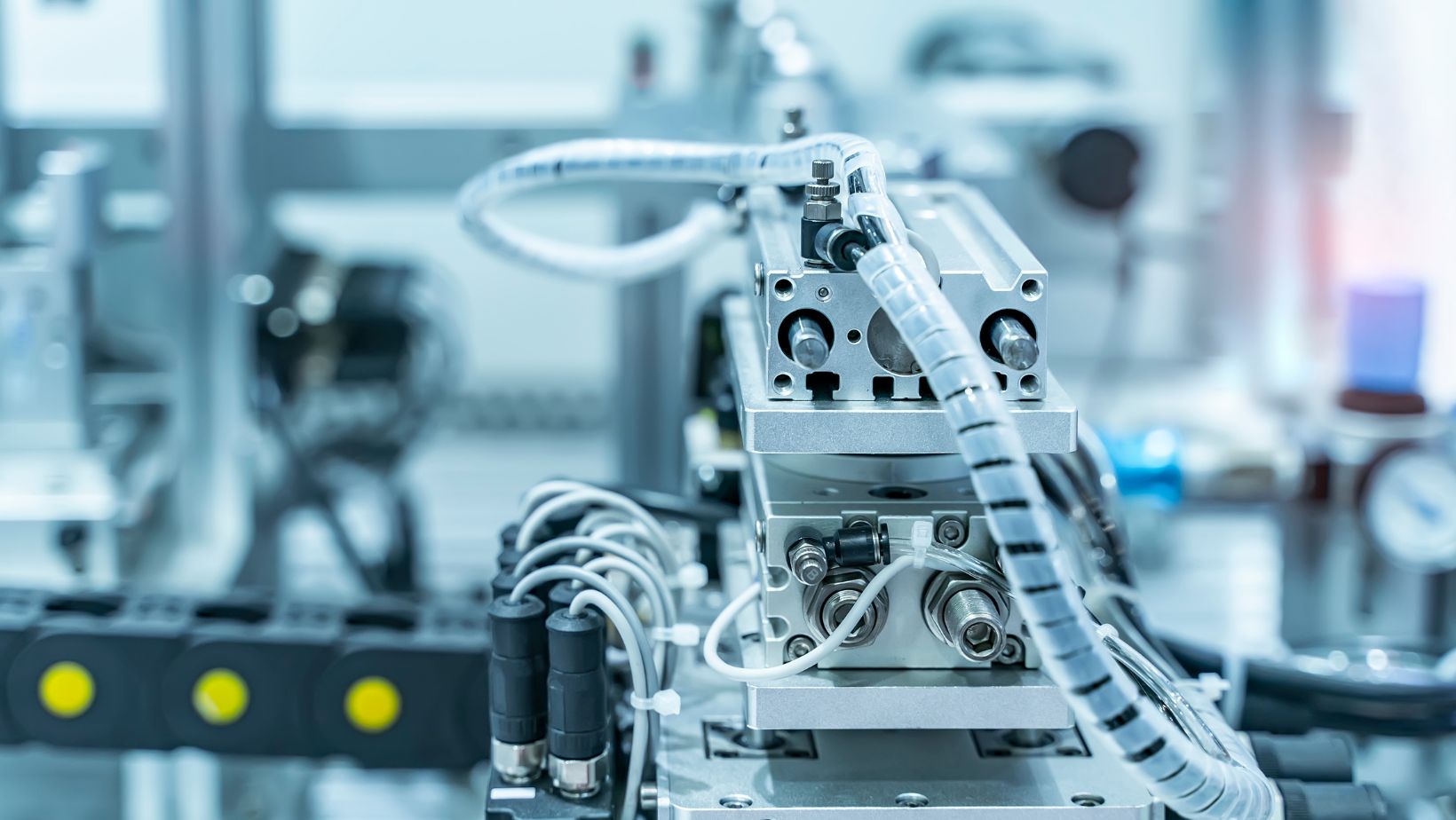

Pneumatic cylinders are widely used in industrial automation and are involved in many applications, including assembly lines and robotic arms. Choosing the right pneumatic cylinder manufacturers is crucial in making sure that your equipment runs smoothly, safely and effectively. This article aims at discussing how one can be able to select the right pneumatic cylinder suppliers that will be able to meet the automation needs of an organization while at the same time offering value for the money that is spent.

Understand Your Specific Needs

However, to be able to choose the right pneumatic cylinder company, you need to know what you are looking for. Depending on the application, the pneumatic cylinders can be single acting, double acting, telescopic or rodless. Think about the force, speed and stroke length that is needed for your applications. Also, consider the conditions under which the cylinders will be used—will they be exposed to high temperatures, humidity, or corrosive agents? These are the needs that will enable you to convey your message to the suppliers and get the products that suit your needs. This initial step is important because it helps you narrow your search to suppliers who can provide products that meet your operational needs to the letter, thus eliminating potential future problems or mismatches. Furthermore, understanding your needs enables you to avoid over-designing which is costly or under-designing which compromises the system.

Research Pneumatic Cylinder Manufacturers

After defining your requirements, start searching for the potential suppliers of pneumatic cylinders. It is recommended to work with companies that have a good reputation in the industry. You can begin with their websites to look for product brochures and also read the customers’ feedback and recommendations.

Also, industry forums and trade shows can be great sources of primary information concerning the dependability and quality of various manufacturers. Think about the types of products they have and if they have worked with businesses in related fields to yours. It is also important to look into how long the company has been in business as this will help in determining the stability of the company and its ability to deliver on long term supply and service contracts. Comparing different manufacturers also allows you to see more options in terms of technology and improvements that are out there in the market which might be offered to you.

Assess Technical Competence and Assistance

When selecting a pneumatic cylinder supplier, it is essential to consider the technical knowledge and customer service. A good pneumatic cylinder company should offer a quality product but also should have the knowledge to assist you in incorporating their products into your systems. See if they provide custom engineering services, which can be a plus if your applications are special and may need special solutions. Also, evaluate the friendliness of their customer service and the accessibility of the technical support, which may be necessary in the future for repairs and other issues. A supplier who offers technical support and customer care shows that they care for the customer and is likely to be a good partner in case of any complications during the life cycle of the product. This can also serve as an indication of their service quality and customer orientation from the detailed documentation and training materials they can offer.

Verify Certification and Quality Standards

To be certain that you are getting a quality and safe product, make sure that the pneumatic cylinder manufacturers meet the set standards and certifications. ISO 9001 is an example of a certification that shows that a manufacturer has a quality management system and complies with the international standards. These certifications can be a good sign that the supplier is serious about quality and reliability. Also, verify if their products have any special certifications that are required for your line of business as this is very important for compliance and safety. Another way of getting more confident in the supplier is to ensure that they follow strict quality control measures in the production of the cylinders to guarantee their durability and safety for use in handling your business operations. These standards are not mere formalities; they are a sign of a supplier’s commitment to provide quality products that meet the needs and expectations of the customers and the law.

Price Comparison and Value Proposition

Although price should not be the only criteria when selecting a pneumatic cylinder supplier, it remains one of the most influential factors. Once you have eliminated the cylinders that do not meet the above criteria, compare the prices of the cylinders that meet your requirements. Do not focus only on the price but also on the cost, which includes such aspects as maintenance costs, service life, and efficiency of the product. Some of the pneumatic cylinder manufacturers may provide extra service such as longer warranty period, shorter lead time, or better customer support, which can further reduce cost and improve productivity.

Another area that should be compared is the possibility of obtaining a lower price due to the possibility of concluding a contract for a large amount or a long-term cooperation. Assessing these factors enables one not only to identify the supplier that offers the lowest price but also the one that can offer significant assistance and value in the future.

To sum up, the process of selecting the appropriate pneumatic cylinder supplier requires a lot of effort and the definition of the requirements. By evaluating potential suppliers in terms of the products they offer, the technical skills they possess, the quality of their products, and their overall worth, it is possible to form a partnership that improves the effectiveness and dependability of your automation systems. When it comes to pneumatic cylinder, it is important to deal with a company that not only provides quality pneumatic cylinder but also quality service that will help in the smooth running of your industrial applications. If you take time and think through your choice, you will be in a position to choose the right supplier that will help you achieve your objectives and goals in business hence making the relationship between the two of you fruitful.