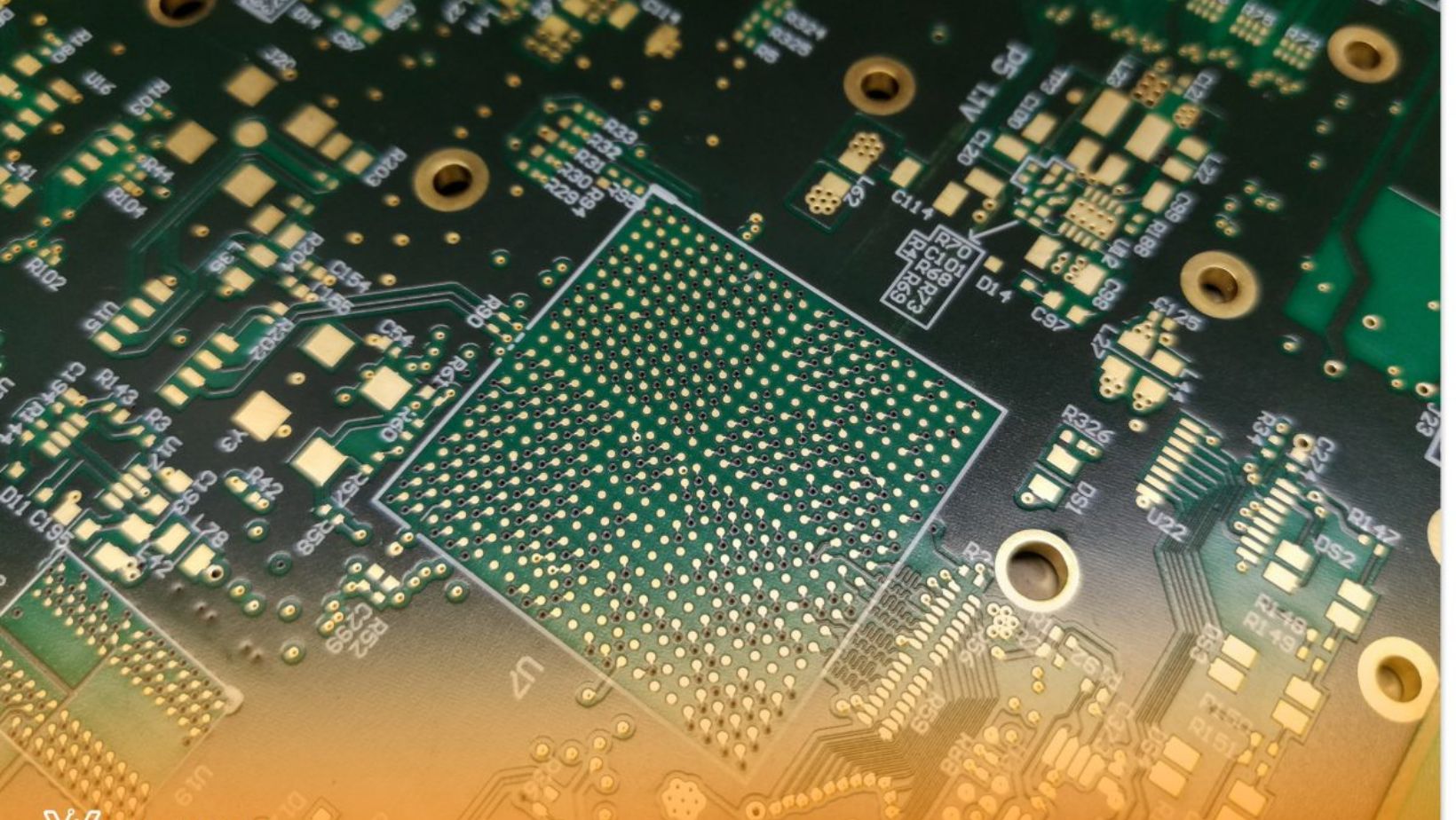

If you examine modern commercial electronics, you’ll notice they’re packed with tiny components. Even your iPhone, microwave, and PC have them on their circuit boards. Instead of using traditional components, PCB manufacturers attach these components directly onto the board’s surface using specialized machines. Most of these components are quite small. The technology behind this mounting process is called Surface Mount Technology (SMT). So, what exactly is SMT, and what are its advantages? Let’s explore SMT technology in more detail.

What is SMT Technology?

Surface Mount Technology (SMT) is a standard procedure in electronic circuit assembly today. Many PCB manufacturers rely on SMT to produce their boards.

SMT involves mounting electronic components directly onto the surface of PCBs. It differs from Plated Through-Hole Technology (PTH) and serves as an excellent replacement or alternative.

With SMT, even the most complex electronic circuit boards can be easily built.

This technology allows for the creation of smaller assemblies with exceptional repeatability.

This is all thanks to the high levels of automation and precision associated with SMT.

Many manufacturers now utilize this technology, enabling them to design small, lightweight, and compact PCBs rapidly. Moreover, it’s a much faster process compared to through-hole technology.

SMT doesn’t require excessive work during assembly.

It’s a simple process of picking and placing PCB components onto the board.

SMT IC Package Types

Numerous SMT packages facilitate the mounting of circuit chips. Here are some common ones for your PCB:

- Ball Grid Array (BGA): This type has tiny solder balls on the chip’s bottom surface, making it denser.

- Quad Flat Package (QFP): A QFP is rectangular or square with leads extending from each side.

- Small Outline Package (SOP): SOP is compact, saving space on a circuit board and offering better mechanical stability.

- Quad Flat Non-leaded package (QFN): QFN has no leads and uses small metal pads to attach an IC to the board.

- Small Outline J-lead package (SOJ): These packages have ‘J’-shaped leads protruding from two opposite sides.

- Lead Grid Array (LGA): The LGA connects to the PCB via metal pads.

Advantages of SMT

SMT offers several advantages:

- Reduced Manufacturing Costs: SMT allows for smaller PCB designs, leading to lower manufacturing costs. Components can be placed close together on the board, further reducing costs.

- Improved Work Efficiency: SMT improves work efficiency, making it a preferred choice for many PCB manufacturers. Tasks can be completed within a single workday, much faster than PTH technology.

- Simpler Overall Structure: SMT-manufactured boards have a simpler structure compared to PTH-assembled boards. They don’t require complex processes like drilling.

- Less Error-Prone: SMT is less prone to errors than PTH. It’s easier to correct minor mistakes on SMT boards, making it a preferred method for high-volume production with fewer errors.

- Adaptable to Smaller Components/High Component Density: SMT allows for easy placement of components on both sides of the board at higher densities. More connections and features per unit area can be achieved.

- Higher Connection Density: SMT enables the delivery of specific-sized signals within a given time, even in tight spaces.

- Fewer Holes Needed: SMT is cost-effective as it requires fewer holes to be drilled on the circuit board.

- Low Radiation Emission: SMT assembly results in lower radiation emissions, making it a safer assembly method.

- Better Electromagnetic Compatibility (EMC): SMT allows for compact packaging with lower lead inductance, resulting in a smaller radiation loop area and excellent EMC performance.

Application of SMT

SMT technology enables the integration of more electronic components into smaller spaces on a PCB.

It’s a technology that will continue to grow in the coming years.

If you’re a printed circuit board assembler, SMT is an excellent choice, even though it might be slightly more expensive.

The Future of SMT

SMT is here to stay and will likely continue to evolve.

Summary

SMT offers numerous advantages, including cost-effectiveness, faster manufacturing times, and efficient use of board space.

The lower setup and manufacturing costs are another significant benefit of SMT.

If you have an upcoming SMT PCB project, contact us today to learn more about PCBs.