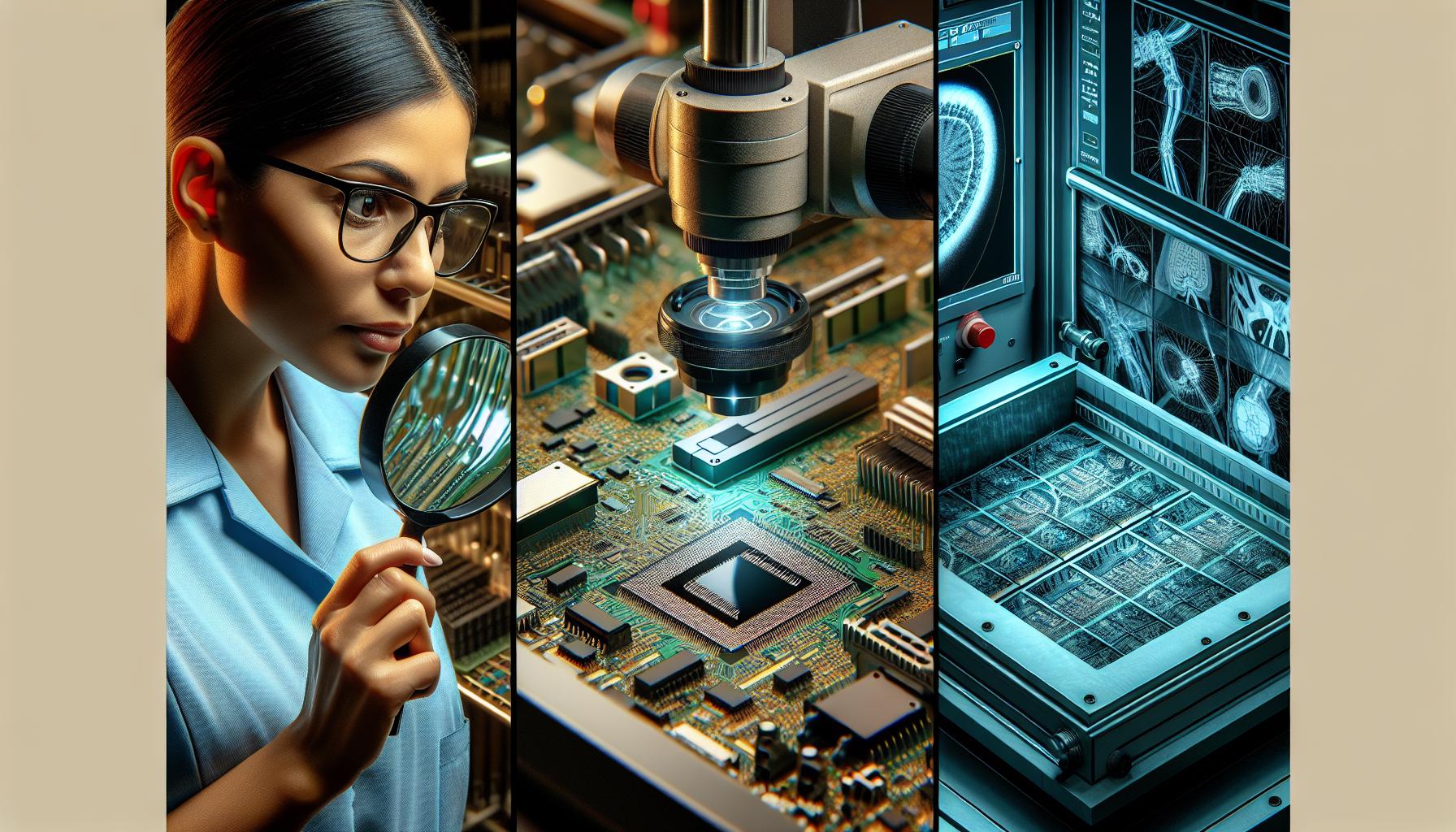

In the world of electronics, printed circuit boards (PCBs) are the backbone of countless devices, making their reliability crucial. Detecting defects early can save time and resources while ensuring optimal performance. This article explores effective methods for checking PCB defects, highlighting techniques that help maintain quality and prevent costly failures.

Understanding PCB Defects

PCB defects are discrepancies in printed circuit boards that can impact performance and reliability. Early detection is crucial for ensuring functionality and preventing costly failures.

Common Types of PCB Defects

- Open Circuits: These occur when a connection is incomplete, preventing electrical flow.

- Short Circuits: These arise when two conductive paths unintentionally connect, causing excess current.

- Broken Traces: Damage to the copper traces can disrupt the circuit’s integrity.

- Soldering Defects: Issues like cold joints or insufficient solder can impair connections.

- Component Misplacement: Incorrectly positioned components can affect the functionality of the PCB.

- Manufacturing Errors: Mistakes during fabrication can lead to open or short circuits.

- Environmental Factors: Heat, humidity, and exposure to chemicals can degrade PCB materials.

- Improper Handling: Physical stress during assembly or transport can damage PCBs.

- Design Flaws: Inadequate design can result in unanticipated stress on circuits and connections.

- Aging Components: Over time, materials can degrade, causing various defects.

Inspection Methods

Inspection methods play a crucial role in identifying PCB defects. They ensure that the boards meet quality standards and function correctly. Several established techniques help in detecting these issues.

Visual Inspection

Visual inspection involves examining the PCB with the naked eye or magnifying tools. Inspectors look for visible defects like cracks, solder faults, and misaligned components. This method is quick and cost-effective but has limitations in detecting smaller defects. It’s effective for initial assessments, especially during the assembly process.

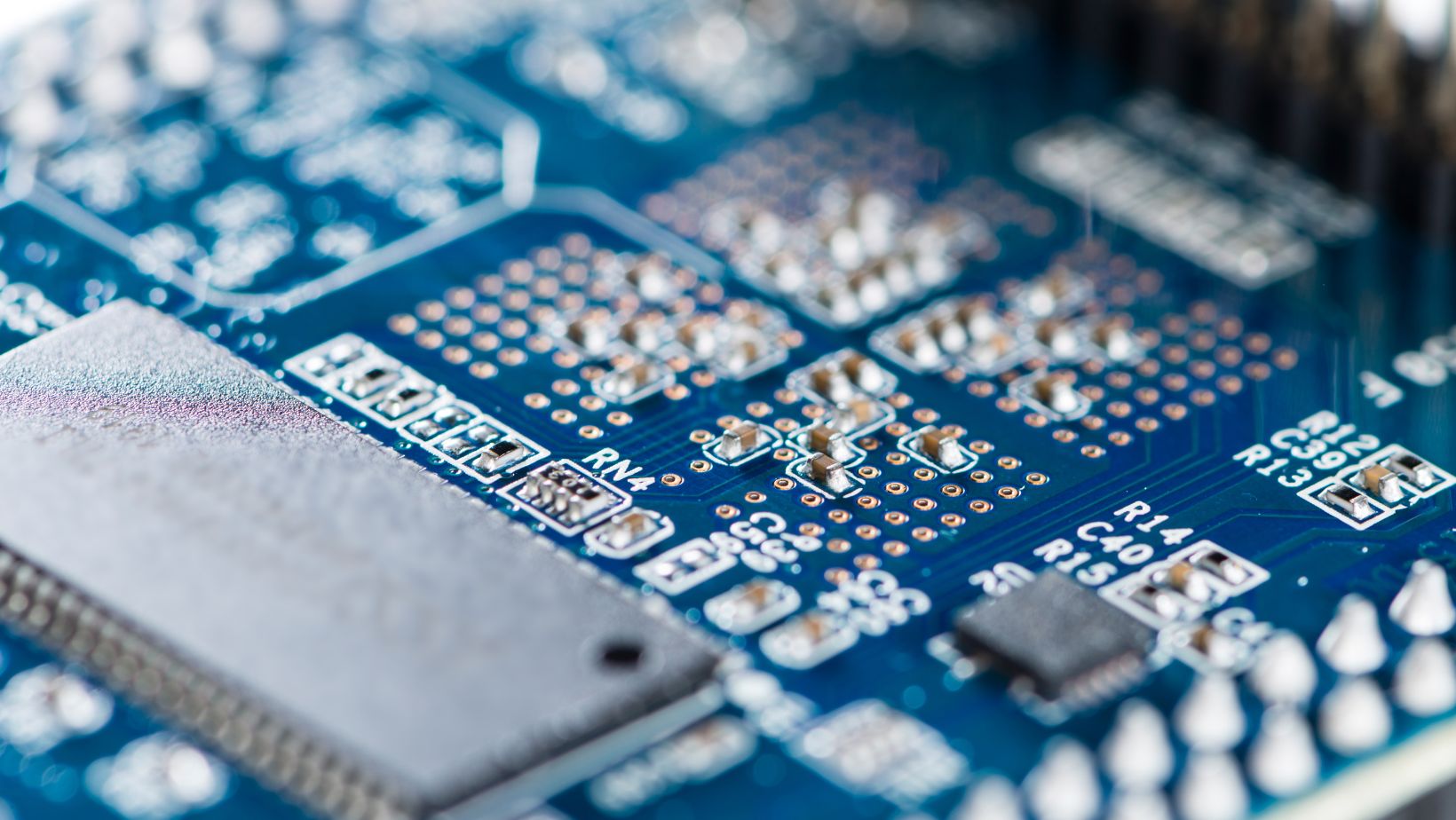

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) utilizes advanced cameras and software to scan the PCB for defects. This method provides high accuracy and speed, allowing for the detection of issues such as missing solder, incorrect components, and alignment errors. AOI systems can compare the scanned images against predefined standards, significantly reducing human error and increasing efficiency.

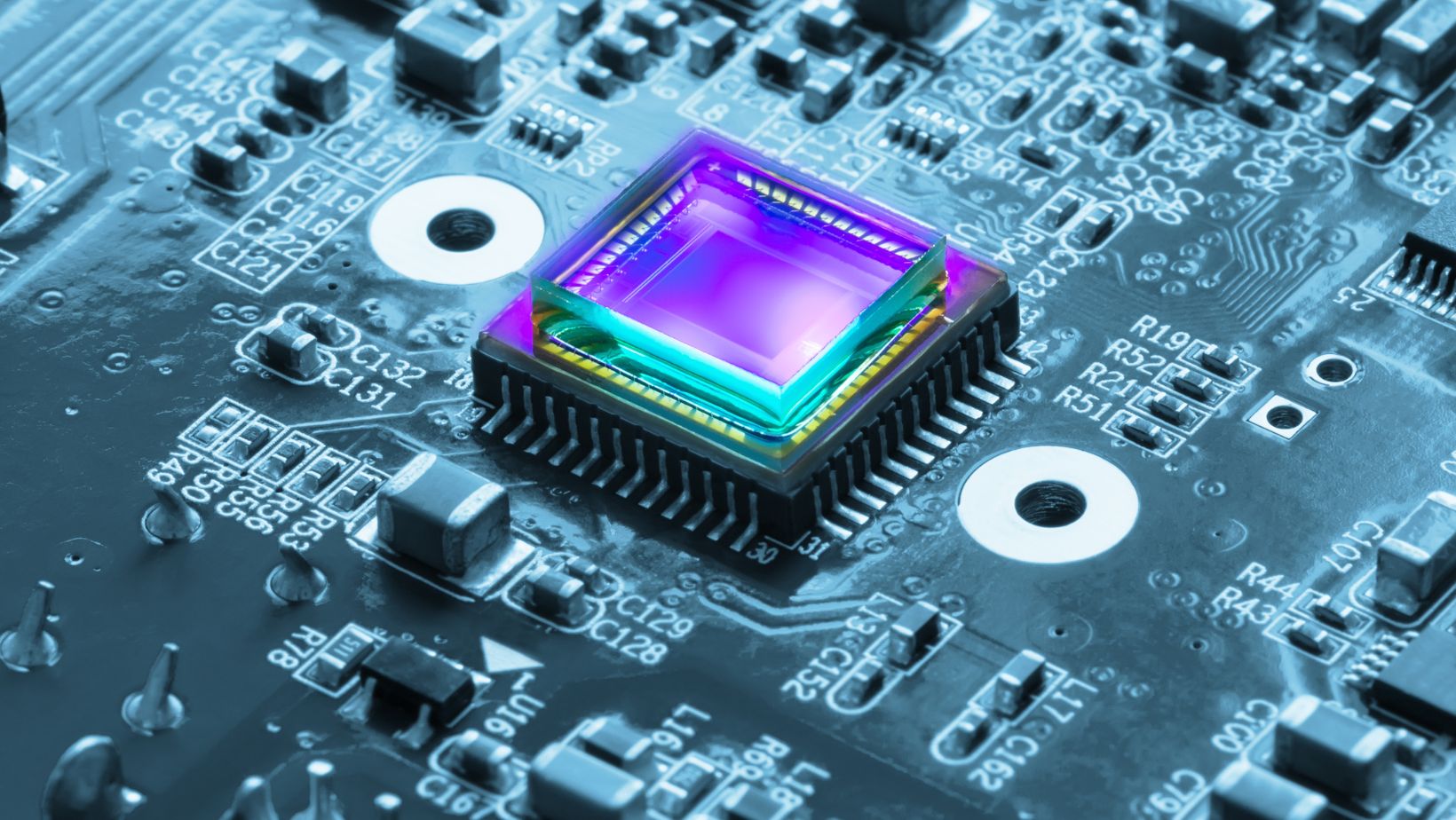

X-Ray Inspection

X-Ray inspection uses X-ray imaging to reveal defects hidden from the surface. This method is particularly useful for multi-layer PCBs, where internal connections are critical. For those seeking detailed and reliable X-Ray inspection services, ourpcb.com provides excellent solutions.

It detects problems such as solder joint defects, misplaced components, and internal short circuits. X-Ray inspection offers detailed visualization, ensuring thorough quality control for complex assemblies.

Testing Techniques

Testing techniques for printed circuit boards (PCBs) play a crucial role in identifying defects and ensuring quality. Two prominent methods include electrical testing and functional testing.

Electrical Testing

Electrical testing evaluates the electrical performance of the PCB. This testing checks for continuity, shorts, and open circuits, ensuring all connections function correctly. It uses techniques such as in-circuit testing (ICT), which examines individual components on the PCB while assessing their connections. Additionally, flying probe testing offers flexibility by allowing quick checks of specific points on the PCB without needing a dedicated test fixture. Both methods efficiently detect defects that could compromise the circuit’s performance.

Functional Testing

Functional testing assesses the PCB’s performance in real-world conditions. This testing ensures that the PCB meets its intended specifications under operational scenarios. Typically, functional testing involves loading the device with software that simulates expected usage. This method checks various functions, such as signal integrity, response time, and overall reliability. By simulating actual operating conditions, functional testing confirms that the PCB operates correctly and efficiently in its intended application.

Preventive Measures

Implementing effective preventive measures plays a vital role in minimizing PCB defects. Regular quality checks and thorough design considerations help ensure that PCBs maintain their intended functionality.

Quality Control Practices

Quality control practices are essential for maintaining high standards in PCB production. These practices include:

- Routine Inspections: Regular inspections at various stages of production identify potential defects early.

- Standard Operating Procedures (SOPs): Establishing SOPs ensures consistency in production processes, reducing the risk of errors.

- Training Programs: Conducting training for staff on quality standards and inspection techniques enhances their ability to detect defects.

- Data Analysis: Using data trends from past defect occurrences assists in identifying common failure points, allowing for targeted improvements.

- Supplier Quality Management: Ensuring that suppliers meet quality standards prevents materials that may lead to defects in final products.

Design Considerations

Design considerations significantly influence the likelihood of PCB defects. Critical factors include:

- Component Placement: Strategically placing components prevents overcrowding and enhances heat dispersion, leading to improved reliability.

- Design for Manufacturability (DFM): Applying DFM principles simplifies assembly processes, reducing errors during production.

- Thermal Management: Integrating appropriate thermal management elements, such as heat sinks, mitigates overheating-related failures.

- Signal Integrity: Designing for optimal signal integrity minimizes issues such as crosstalk and impedance mismatch, which can lead to electrical failures.

- Testing Integration: Incorporating test points and features within the design facilitates easier and more effective electrical testing.

Utilizing these preventive measures optimizes PCB production and helps maintain quality throughout the manufacturing process.

Conclusion

Detecting PCB defects early is crucial for maintaining high-quality standards in electronics manufacturing. By utilizing a combination of inspection methods and testing techniques, manufacturers can identify issues before they escalate. Emphasizing preventive measures and robust quality control practices further enhances the reliability of PCBs. Continuous improvement in design and testing processes not only minimizes defects but also optimizes production efficiency. Ultimately, a commitment to quality assurance leads to better performance and longevity of electronic products.